Blue Sky Thinking

Hemp News, Views

& Articles

Filter by category

Hemp In The News |

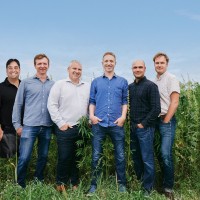

Blue Sky Hemp Ventures Sells Hemp Food Division to Fresh Hemp Foods to Focus on Cannabis Extracts and Contract Manufacturing

Blue Sky Hemp Ventures has sold its hemp food division to Fresh Hemp Foods to focus on expanding its cannabis extraction and contract manufacturing business. The move supports growth in products like vapes, oils, and softgels, and positions the company for global expansion through EU-GMP certification.

A Better Hemp Oil for Modern Applications

At Blue Sky Hemp Ventures, our journey with hemp seed oil began the way it does for most - cold-pressing high-quality, food-grade Canadian hemp seeds to create a rich, green…

Hemp History Month: 10,000 Years of Growth

Move over kale and step aside bamboo — hemp is the original multi-tasker, and it’s been quietly shaping human civilization for thousands of years.

Global Hemp Horizons: How Trust Became Canada’s Ultimate Export Advantage

As trade winds evolve, Canada—with Blue Sky Hemp Ventures at the forefront—is transitioning from being a dominant U. S. supplier to becoming the world's hemp partner of choice.

Canada’s Hemp Export Edge: The Global Trust Advantage

As trade winds evolve, Canada—with Blue Sky Hemp at the forefront—is transitioning from being a dominant U. S. supplier to becoming the world's hemp partner of choice.

Hemp Foods | Hemp In The News |

Tariffs, Trade, and Transformation: Why Blue Sky Hemp is Betting Big on the World Stage

While all Canadian exporters are bracing for the impact of new U. S.